SEA WATER ANOLYTE GENERATORS

NEW OPPORTUNITIES - NEW APPLICATIONS

The use of seawater as feed brine for Envirolyte generators of activated (disinfecting and washing) solutions has always been a challenge and great temptation for the scientists and engineers of Envirolyte Industries International Ltd. The reasons for that are quote obvious: eliminating the need for any source of mains water and preparation of brine makes the Envirolyte technology even simpler and more cost effective. Moreover, it moves the horizons for the use of the technology to the previously untouched areas of all type off shore/on board or/and aquaculture applications wherever there is a need for disinfection, sterilization and water purification.

The idea of the seawater to be used as the main and the only feed for Envrolyte units lies in the chemistry of the sea water which is predominantly sodium chloride solution accompanied by some other salts. The concentration of sodium chloride is sufficient to generate the necessary volume of active chlorine to render disinfecting properties to the final product - anolyte generated purely of the seawater.

Envirolyte sea water machines is a further development of Envirolyte technology to suite our customers needs for disinfection and water purification in aquaculture industry and in off shore/on board operations.

Envirolyte sea water machines have been designed to generate ANK-neutral anolyte and catholyte, if needed, out of the sea water with salinity ranging from 5-7 PSU ( brackish water) to 33-35 PSU (ocean water), with active chlorine concentration in the range of 500 pm-1000 ppm.

|

Envirolyte sea water machines have been designed to generate ANK-neutral anolyte and catholyte, if needed, out of the sea water with salinity ranging from 5-7 PSU ( brackish water) to 33-35 PSU (ocean water), with active chlorine concentration in the range of 500 pm-1000 ppm.

THE KEY FEATURES

- Full automation and easy operating procedures give the added benefits to rapid delivery of safe and fast acting disinfectant -ANK -neutral anolyte.

- The strength of ANK-neutral anolyte in terms of active chlorine concentration is preset during manufacturing but can be adjusted according to customers requirements.

- The control system of Envirolyte seawater units is simple and easy to operate. It can be altered to suit different applications and conditions.

- Flow and pressure controllers are installed in the Hydraulic part to stop the Envirolyte unit if there is interruption of water supply and to start it as soon as water flow resumes.

- Variable brine pump ensures a required dosage at any given time.

- The enclosures are made of non-corrosive materials. Various types can be provided according to the customers demand.

- Tubes and connectors are of EPDM/PVDF plastics and are highly resistant against aggressive solutions.

- All input and output connectors are located on the sides of the boxes to allow them wall-mountable.

- A simple on/off switch with power indicator allows starting and stopping Envirolyte seawater units manually.

- Level switches or ORP meter enable to start and stop Envirolyte seawater units automatically.

- Reset button allows starting the unit regardless of the level switchers' position.

- Alarm is inbuilt in the unit but can be arranged in any remote area through external connection.

- PC/Internet control is optional for all Envirolyte seawater units, which allows monitoring the operation of the unit, diagnose and remedy any potential problem from a control room at any location and distance form the installation site.

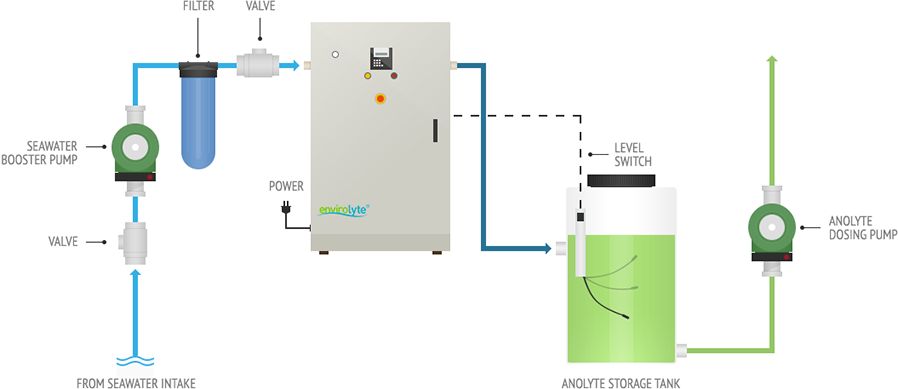

General layout of Envirolyte seawater anolyte generator

GENERAL SPECIFICATIONS

- Envirolyte seawater units are manufactured with output capacity ranging from 40 LPH up to 6000 LPH of ANK- neutral anolyte;

- Envirolyte seawater units are assembled in our traditional polycarbonate, stainless steel or steel finished with powered technology, reinforced polyester or chromate aluminium enclosures;

- Power source 380/230/110 VAС ±10%;

- Power consumption depends on the model and may vary from 740 W/H to 10, 5 KWT/H;

- Feed water - seawater with the salinity ranging from 5-7 PSU up to 33-35 PSU;

For instruction details or applications please send Your enquiry..